The new plan of the big brands for plastic waste: boot and burn ► América Economy ► América Economy

The global consumer goods industry's plans to dispose of the vast amounts of plastic waste it generates can be seen at a landfill site outside the Indonesian capital, where a swarm of bulldozers tear apart stinking mountains of rubbish.

The machines dig up trash to provide fuel for a nearby cement plant. Discarded bubble wrap, takeaway food containers and single-use shopping bags have become one of the fastest growing sources of energy for the global cement industry.

The Indonesian project, funded in part by Unilever PLC, maker of Dove soap and Hellmann's mayonnaise, is part of a global effort by big multinationals to burn more plastic waste in cement kilns, Reuters reports for the first time. time.

"Fuel" isn't just cheap and plentiful. It is the centerpiece of a partnership between the consumer products giants and cement companies aimed at polishing their environmental credentials. They promote this approach as a benefit to a planet suffocated by plastic waste.

Companies argue that converting plastic to energy prevents it from being dumped in landfills and oceans and allows cement plants to stop burning coal, a major driver of global warming.

Reuters has identified nine collaborations launched in the past two years between consumer goods giants and big cement makers. Four of the main manufacturers of plastic containers participate: The Coca-Cola Company, Unilever, Nestle S.A. and Colgate-Palmolive Company. On the cement side there are four large producers: the Swiss Holcim Group, the Mexican Cemex SAB de CV, PT Solusi Bangun Indonesia Tbk (SBI) and Republic Cement & Building Material Inc, a Philippines company.

The projects span several countries, from Costa Rica to the Philippines, passing through El Salvador and India. In Indonesia, for example, Unilever has partnered with SBI, one of the country's largest cement manufacturers.

The alliances come to light as the cement industry - which generates 7% of the world's carbon dioxide emissions - faces mounting pressure to reduce greenhouse gases. Consumer brands, for their part, are feeling pressure from legislators who ban or tax single-use plastic containers and promote the so-called "polluter pays" so that producers assume the costs of cleaning it.

Critics say there is little green about burning petroleum-derived plastic to make cement. A dozen sources with direct knowledge of the practice, including scientists, academics and environmentalists, told Reuters that plastic burned in cement kilns emits harmful air emissions and is the equivalent of swapping one dirty fuel for another.

More importantly, according to environmental groups, this is a strategy that could undermine efforts around the world to increase recycling rates and drastically reduce the production of single-use plastic. .

It's a naive way of thinking, said Axel Pieters, chief executive of Geocycle, the waste management arm of the Holcim Group, one of the world's largest cement makers and partner of Nestlé, Unilever and Coca-Cola on projects plastic fuel. Pieters explained to Reuters that burning plastic in cement kilns is a safe, cheap and practical solution that allows large volumes of this rubbish to be disposed of quickly.

Less than 10% of all plastic ever made has been recycled, largely because it's too expensive to collect and sort. Meanwhile, plastic production is projected to double in 20 years.

"To think we're only going to recycle waste and avoid plastic is to believe in fairy tales, and you can quote me on this," said Pieters.

Unilever declined to comment specifically on the Indonesia project. In an email, he said that in situations where recycling is not feasible, he would explore "energy recovery initiatives." This is industry jargon for burning plastic for fuel.

Coca-Cola, Unilever, Colgate and Nestlé did not respond to questions about the environmental and health impacts of burning plastic in cement kilns. The companies said they invest in various initiatives to reduce waste, such as increasing the recycled content in their packaging and making refillable packaging.

Cemex, SBI, Republic Cement and Holcim's Geocycle unit told Reuters their partnerships with consumer goods companies were aimed at tackling the global waste crisis and reducing their reliance on traditional fossil fuels.

It is not known exactly how much plastic waste is burned in cement kilns around the world. This is because industry statistics often lump them into a broader category called "alternative fuel" that includes other waste such as scrap wood, old tires and clothing.

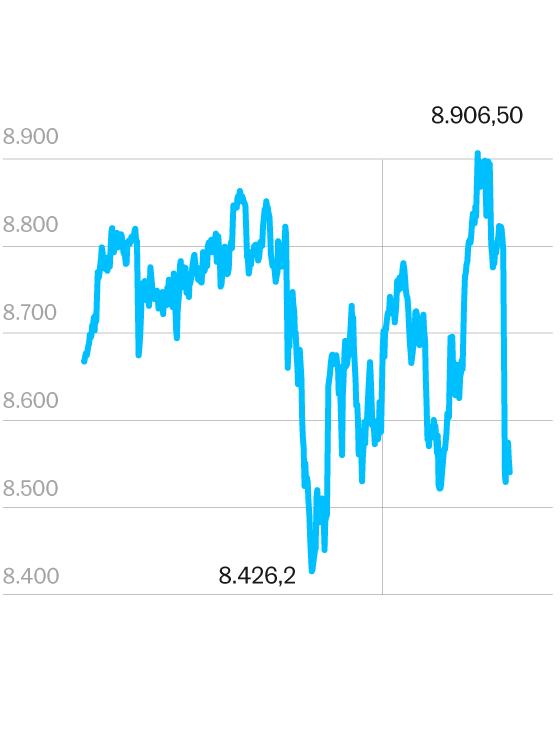

The use of alternative fuels has increased steadily in recent decades and is already the dominant energy source in the cement industry in some European countries. There is no question that the amount of plastic within that category has risen and will continue to rise given the global explosion of plastic waste, according to 20 cement industry players interviewed for this report, including business executives, engineers and analysts.

Reuters also reviewed data from cement associations, individual countries and analysts that confirmed this trend.

For example, Geocycle currently uses 2 million tonnes of plastic waste a year as alternative fuel at Holcim plants around the world, according to Geocycle CEO Pieters, who said the company intends to increase this figure to 11 million tons by 2040, if necessary through further partnerships with consumer goods companies.

Pieters stated that the cement industry has the capacity to burn all the plastic waste that is currently produced in the world. The United Nations Environment Program estimates that figure to be 300 million tons per year. That dwarfs the world's plastic recycling capacity, which is estimated at 46 million tons a year, according to a 2018 report by the Organization for Economic Co-operation and Development (OECD), a global policy forum.

Plastic pollution, meanwhile, is plaguing communities whose landfills are reaching capacity and encroaching on Earth's wild places. Plastic trash reaching the oceans will triple to 29 million tons a year by 2040, according to a study published last year by the Pew Charitable Trusts. The debris is endangering wildlife and contaminating shellfish eaten by humans.

"The cement industry is definitely a solution," says Geocycle's Pieters.

Toxic emissions

Consumer goods giants are turning to cement companies for help reducing plastic litter, while other initiatives stumble. Reuters reported in July that a set of new "advanced" plastics recycling technologies promoted by big brands and the plastics industry have suffered major setbacks around the world.

2021-10-28t180747z_1_lynxmpeh9r150_rtroptp_4_environment-plastic-cement.jpg

Cement manufacturing is one of the most energy-intensive businesses in the world. Fuel - mainly coal - is its biggest expense, according to industry executives. In the 1970s, producers looking to cut costs began feeding waste such as tires, biomass, sewage sludge and plastic into kilns. These materials are not as effective as charcoal, but they are virtually free. Some local governments even pay cement manufacturers to accept this waste.

In Europe, waste already represents almost half of the fuel used by the cement industry. In Germany, the block's largest producer, the proportion is 70%, according to 2019 data from Global Cement & Concrete Association (GCCA), a trade organization which is based in London.

The United States uses 15% alternative fuel in its kilns, according to the Portland Cement Association, a US industry group. Its spokesman, Mike Zande, stated that its members have the capacity to catch up with Europe.

While cost reduction remains the main driver, in recent years the industry has begun to promote junk fuel as a way to reduce the "societal problem" of plastic waste, said Ian Riley, managing director of the World Cement Association (WCA), which is based in London and represents producers in developing countries.

So it made sense for cement manufacturers to partner with consumer goods companies, the largest source of single-use plastic packaging, to burn discarded plastic in their kilns.

In emerging markets, big brands sell a lot of food and hygiene products packaged in plastic bags, usually single servings tailored to the budgets of poor households. Billions of these flexible packages are sold every year. Envelopes are almost impossible to recycle because they are made of layers of different materials laminated together, usually plastic and aluminum, which are difficult to separate.

Indonesia, an archipelago of more than 270 million people, is the second largest contributor to plastic pollution in the oceans, behind China, in part due to widespread sachets, according to a 2015 study published in Science magazine. Plastic trash can be seen everywhere in Jakarta, the sprawling capital of more than 10 million people. It clogs storm drains, litters its slums, and mars its coastline.

Developing countries often welcome help with waste management. Thus, Indonesia was a natural location for Unilever's waste business with cement maker SBI and the local government of Jakarta. At last year's presentation, Andono Warih, head of Jakarta's environment service, praised the initiative and expressed hope that it would spark more such collaborations.

The project uses plastic already buried in the Bantar Gebang landfill, one of the largest in Asia. The waste excavated by earthmoving machinery is transported to a warehouse at the landfill. There they are crushed, sieved and dried to a brown, dung-like mixture. That material, known as Refuse Derived Fuel (RDF), is fed into the kiln at an SBI cement plant in Narogong, just outside Jakarta.

SBI currently uses 20% CDR at that plant, a figure that could rise to 35%, according to Ita Sadono, SBI's director of business development. The operation still relies primarily on coal, he said, but he maintains that the RDF is "significantly helping to reduce plastic waste."

Unilever is helping finance a second RDF project in Cilacap, an industrial region of Central Java, according to SBI and a 2020 sustainability report from Unilever's local unit in Indonesia. The two facilities could send 30,000 tonnes of plastic waste a year to SBI's cement plants, according to a Reuters analysis of data provided by SBI.

Unilever did not respond to detailed questions about these projects. Sadono said in a text message that Reuters' calculations were "fine", without elaborating.

About two kilometers from the SBI cement plant near Jakarta, Dadan bin Anton, 63, runs a roadside stall selling plastic sachets of soap, detergent and instant coffee, among which are Unilever brands. He says that he often has trouble breathing and blames the cement factory.

"People here breathe dust every day," he said.

SBI has invested in mitigation measures to reduce dust at plants, Sadono said. And it's not clear if the cement installations have anything to do with Dadan's burning chest. Jakarta has some of the dirtiest air in Asia. Pollutants from industrial smokestacks, agricultural fires, and automobile exhaust routinely blanket the city.

But some scientists say incinerated plastic is a dangerous new ingredient added to the mix, especially in developing countries where air quality standards are often weak and unevenly enforced.

Plastic when burned releases harmful substances such as dioxins and furans, said Paul Connett, a retired professor of chemistry and environmental toxicology at St. Lawrence University in Canton, N.Y., who has studied the poisonous byproducts of plastic. waste burning. According to Connett, if enough of these contaminants escape from a cement kiln, it can be dangerous to people and animals in the surrounding area.

The fears are exaggerated, said Claude Lorea, director of cement at GCCA, the industry group that represents big cement companies including Holcim and Cemex. Superheated furnaces destroy all toxins resulting from burning any alternative fuel, including plastics and hazardous waste.

But things can go wrong.

In 2014, a highly toxic and suspected human carcinogen, hexachlorobenzene (HCB) was released by a cement factory in Austria after the facility burned industrial waste contaminated with the pollutant. The Austrian agency for health and food safety found that cheese and milk from cattle raised near that plant in the southern state of Carinthia were contaminated. And blood samples taken from area residents also contained HCB, which can damage the nervous system, liver and thyroid.

An investigation commissioned by the state government uncovered multiple failures by local regulators and the cement factory, including that the kiln was not operating hot enough to destroy contaminants such as HCB.

The Austrian cement maker that operates the plant, w&p Zement GmbH, told Reuters it had worked to remove all environmental contamination from the incident and had provided help to the community, such as replacing contaminated feed.

Carinthia province spokesman Gerd Kurath said in an email that continued government monitoring of air, soil and water samples in the area shows that pollution levels have decreased.

The cement industry, for its part, advertises the conversion of waste into fuel as a way to fight global warming. This is because burning waste, including plastics, emits fewer greenhouse gases than coal, according to trade group GCCA.

Burning trash "reduces our dependence on fossil fuels," spokeswoman Lorea said. "It's climate neutral."

The European Commission, which sets emission standards in Europe, told Reuters that plastic emits less carbon dioxide than coal, but more than natural gas, another fuel used by the cement industry.

The US Environmental Protection Agency, which regulates environmental policy in the world's largest economy, came to a different conclusion. He said in a statement that there are no significant climate benefits from replacing coal with plastic, and that burning this waste in cement kilns can create harmful air pollution that needs to be controlled.

Measuring CO2 emissions from plastic compared to coal, the world's dirtiest fossil fuel, is not the benchmark to use if the cement industry is serious about fighting global warming, said Lee Bell, adviser to the International Pollutant Elimination Network, a global coalition working to eliminate toxic pollutants. Reducing the industry's huge carbon emissions, he said, requires a switch to fuels like green hydrogen, a more expensive but cleaner fuel produced from water and renewable energy.

"The cement industry should move away from the waste-burning paradigm and move to clean fuels," Bell said.

The GCCA told Reuters the industry is improving energy efficiency and considering the use of green hydrogen.

More and more plastic

As cement factories in industrialized countries prepare to burn more plastic, explosive growth is forecast in the developing world.

2021-10-28t180747z_1_lynxmpeh9r157_rtroptp_4_environment-plastic-cement.jpg

China and India account for 60% of the world's cement production in facilities whose main fuel is coal. In the next decade, these countries have set themselves the goal of using alternative fuels to power between 20% and 30% of their production.

If they reach just 10%, that would equate to burning 63 million tons of plastic a year, up from 6 million today, according to SINTEF, a Norwegian scientific research group. That's more plastic waste than the United States generates each year.

In 2019, 170 countries agreed to "significantly reduce" their plastic use by 2030 as part of a United Nations resolution. But the measure is not binding, and the proposed ban on single-use plastic by 2025 was opposed by several member countries, including the United States.

Therefore, the option of turning waste into fuel may become an unstoppable force, according to Matthias Mersmann, CTO of KHD Humboldt Wedag International AG, a German engineering company that supplies equipment to cement plants around the world. . Plastic waste is rapidly exceeding the capacity of countries to bury or recycle it. Burning removes large amounts of this material quickly, without the need for special handling or new facilities. It is estimated that there are some 3,000 cement plants around the world. All eager for fuel.

"There is only one thing that can stop and break this trend, and that would be a very sharp cut in the production of plastics," said Mersmann. "Otherwise, there is nothing that can stop this."

That push has some environmentalists worried, like Sander Defruyt, who runs a plastics initiative at the Ellen MacArthur Foundation, a UK-based nonprofit focused on sustainability. The foundation developed waste reduction and recycling targets in 2018 with Coca-Cola, Nestlé, Unilever, Colgate-Palmolive and hundreds of other consumer brands.

Defruyt said the foundation does not support its partner companies' shift toward incineration. Burning plastic as fuel for cement, he said, is a "quick fix" that risks giving consumer goods companies the green light to continue producing single-use plastic and could reduce the urgency to redesign containers.

"If you can pour everything into a cement kiln, why worry about the problem anymore?" Defruyt illustrated.

Coca-Cola, Nestlé, Unilever and Colgate-Palmolive said their partnerships with cement companies are just one of several strategies they are pursuing to address the waste crisis.

Plastic prayers

In the central England village of Cauldon, residents have complained in recent years to the council and Britain's environmental regulator about noise, dust and smoke from a nearby cement plant owned by from Holcim. Complaints have failed to prevent the expansion of that facility to burn more plastic.

2021-10-28t180747z_1_lynxmpeh9r14z_rtroptp_4_environment-plastic-cement.jpg

When completed next year, alternative fuel, including "non-recyclable" plastics like potato chip bags, will account for up to 85% of the facility's fuel, according to planning documents submitted to local authorities on behalf of Geocycle, who will manage the project.

According to the documents, energy will be recovered from plastic waste that would otherwise end up in landfills.

Lucy Ford, 42, a Cauldon resident, said the cement company's plans have only heightened fears of emissions among some residents. "They say they are the answer to all our plastic prayers," she said. "I do not like the idea".

Geocycle's Pieters said he understood the community's concerns and that the company complies with all local regulations, carefully monitors emissions from the plant, and that they will be reduced with improvements.

Britain's Environment Agency said in an email that it took all complaints about the plant seriously.

In Indonesia, Unilever and SBI told Reuters it was better to use plastic for energy than leave it in a landfill.

Local environmentalists say they are alarmed that cement kilns could emerge as the solution for a nation awash in plastic waste.

It would allow consumer brands to go about their business as usual, while exacerbating Indonesia's air quality problems, said Yobel Novian Putra, an advocate for the Global Alliance for Incineration Alternatives, a coalition of groups who work to eliminate waste.

"It's like moving the landfill from the ground to the sky," Putra said.

Types of Hats for Kids: The Perfect Hat for Every Occasion

19/05/2022When it comes to dressing up your kids, hats are a great way to add some personality and style. There are so many different types of hats for kids available on the market today, that it can be hard to...